- Температурный максимум – 1200 / 1400°С.

- Термопара S –типа, 1-класса

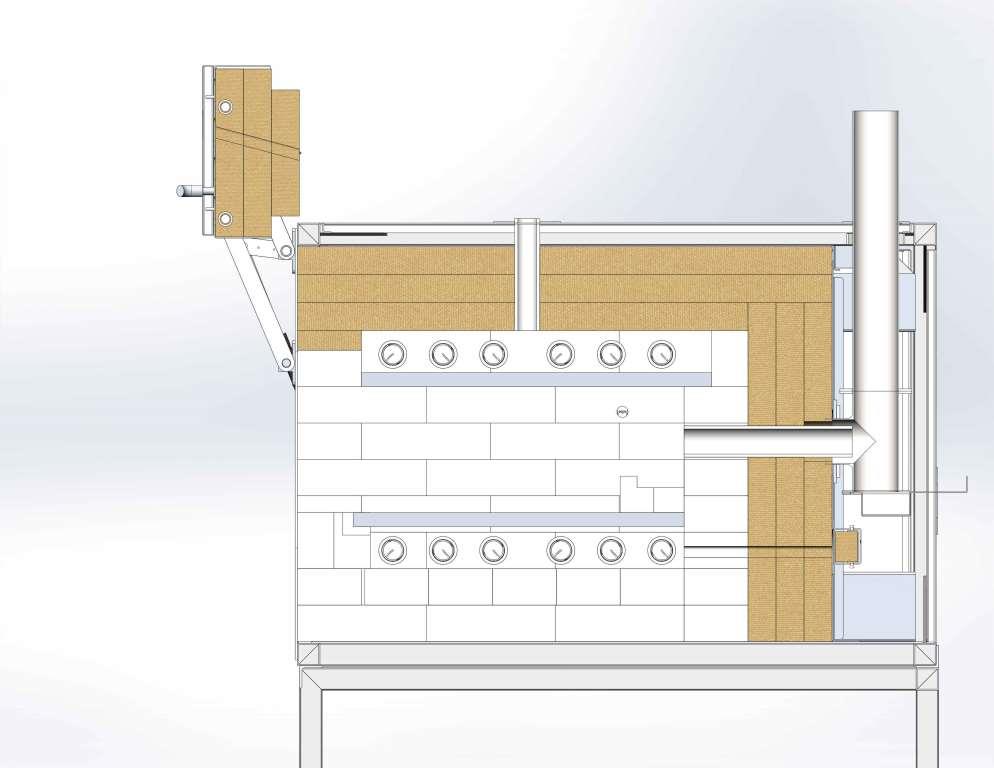

- Исполнение нагревателей – изолированные проволочные нагреватели для высоко агрессивных сред.

- Расположение нагревательных элементов: под и свод печи.

- Защита нагревательных элементы от механических ударов, разлива и агрессивных испарений плитами карбида кремния.

- Защита перегрева печи при помощи, независимой системы контроля температуры.

- Поступление предварительно разогретого воздуха в камеру осуществляется через подовые нагреватели, и исключает случайное захолаживание камеры и образца.

- Плавная регулировки количества поступающего в камеру воздуха достигается шаговой заслонкой.

- Вывод отработанных газов, расположен сзади печи на стене. В вентиляционный канал установлен быстросъемный сборник конденсата.

- Вентиляционные трубы для отвода отработанных газов выполнены из нержавеющей стали.

- Открытие двери, плоско-параллельное, вверх. Для облегчения открытия использованы противовес и газонаполненные амортизаторы.

- При открытии горячая сторона двери обращена от оператора, для защиты от отжегов.

- Дверь печи оснащена керамической проходкой с заглушкой для размещения контрольной термопары.

- Функция отложенного старта для вывода печь на режим к началу рабочей смены.

- Размещение блока электрики возможно в отдельном шкафу, либо моноблоком с печью.

- Вентилируемое межкорпусное пространство печи.

- Подтверждение соответствия измерительного и управляющего оборудования печи.