Высокотемпературные промышленные и ремесленные печи для обжига керамики и термообработки металлов

Производство Tехнологического Оборудования и изготовление Муфельных Печей Агни преображает и улучшает окружающий мир, делая его теплее

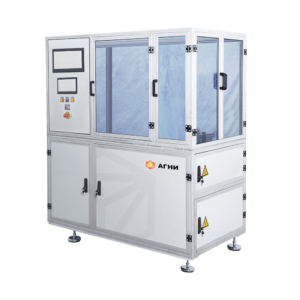

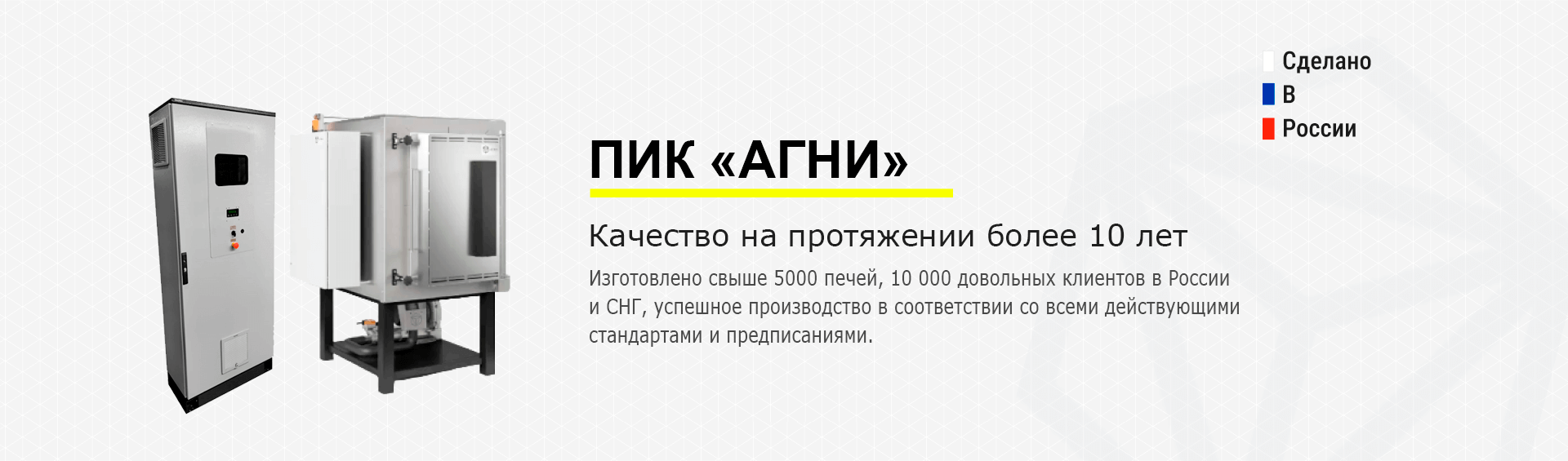

Промышленная компания «АГНИ» — производитель камерных, муфельных, высокотемпературных печей и нестандартного технологического оборудования для микро- и радиоэлектроники. Вдохновленная продукцией мировой фирмы Nabertherm, «АГНИ» является её аналогом на российском рынке. Мы поддерживаем отечественное производство и гордимся участием в программе импортозамещения.

Профессионализм и системный подход к качественному проектированию позволяют непрерывно совершенствовать технологии производства высокотемпературных, муфельных, камерных печей, используя самые передовые термические компоненты. Профессиональная команда инженеров технологов, конструкторов, электриков и проектировщиков всегда следит за последними новшествами в области термообработки. Поэтому на выходе получаются рабочие камеры наивысшего качества, которые обеспечивают однородность и равномерность температуры в каждой муфельной, проходной, туннельной, камерной, высокотемпературной печи. Инновационные методы разработки позволяют просто управлять силовыми шкафами, обеспечивая качественное, безопасное и надежное использование оборудования.

«АГНИ» — первая Российская компания, которая начала системно производить высокотемпературные печи на 1800°C различных видов и назначений. Для быстрого разогрева и четкого регулирования температуры используются особые жаропрочные, огнеупорные, термостойкие материалы внутренней камеры, многослойная керамоволокнистая футеровка и надёжные нагреватели из дисилицид молибдена, карбидокремния и нихрома. Равномерный нагрев и постоянная температура на уровне высоких стандартов позволяют проводить необходимые тесты и совершенствовать технологические процессы термообработки.

Для производства в домашних условиях и на предприятиях в промышленных масштабах

Разработка под заказ

Благодаря огромному опыту учёных в проектировании и изготовлении камерных, туннельных, проходных печей, технологи могут создавать индивидуальные решения под конкретные задачи. Разрабатываем и конструируем рабочие камеры под определенные требования заказчика: оптимальный температурный режим, объём и габариты, специальные системы автоматизации, дистанционное управление, регистрация данных, поверки термопар, инновационные идеи.

Широкий спектр муфельных печей

- для детских и художественных школ искусств

- с циркуляцией и без

- спекание биокерамики и керамических материалов

- удаление пластификаторов, связующего

- установка пирогидролиза

- обжиг технической керамики

- синтез новых материалов

- отжиг тугоплавких порошков

- электролиз расплавов

- подготовка реагентов

- исследование физико-химических свойств сплавов

- лабораторные печи для проведения синтезов в области технической керамики в производстве различных полупроводников.

Задайте вопрос эксперту!

Менеджер компании с радостью ответит на ваши вопросы,

произведёт расчёт стоимости и подготовит коммерческое предложение

Посмотрите видео

о нашей компании «АГНИ»

Закажите свой проект!

Менеджер компании с радостью ответит на ваши вопросы, произведёт расчет стоимости и подготовит коммерческое предложение.